Introduction to Chain Conveyors

What Is a Chain Conveyor?

The chain conveyor is extra than only a tool in present day industries—it is the backbone of efficient fabric transport structures throughout factories, warehouses, and distribution centers. In its only shape, a chain conveyor includes one or extra limitless chains powered via a motor, designed to move substances in a non-stop, green go along with the drift. But don’t permit its simplicity idiot you—this tool is engineered for common standard overall performance, persistence, and precision.

Unlike belt conveyors, the chain conveyor is built for energy. It can circulate heavy or cumbersome masses that would strain or maybe damage wonderful kinds of structures. This is because of the reality the chain conveyor utilizes related metallic chains which could control immoderate-torque programs and abrasive conditions. Whether you are moving pallets, car elements, or crates of soda, a sequence conveyor can control it honestly.

In business environments in which region is tight, and timing is essential, a sequence conveyor offers unmatched flexibility. It can be built to house curves, slopes, and vertical lifts, making it a fantastically adaptable solution. Plus, it’s miles regularly utilized in environments that require synchronization—like in vehicle meeting strains—wherein precision is fundamental.

The excellent detail? The ruggedness and reliability of a series conveyor advise it plays properly below strain without breaking down with out trouble. This translates to reduced downtime, fewer protection headaches, and a greater powerful workflow. So in case you’re wondering why industries maintain counting on chain conveyors, it’s because of the fact they simply art work—successfully and without a result in sight.

Evolution of Material Handling Systems

To surely admire the power of the present day chain conveyor, we have to take a brief enjoy through the facts of cloth handling. Decades in the past, factories and warehouses depended on manual difficult artwork to move products from one element to a few other. It grow to be hard work-in depth, sluggish, and often dangerous.

As name for for mass production accelerated in the route of the Industrial Revolution, the want for automation became clean. Early conveyor structures have been superior the usage of belts and rollers, providing a glimpse into what automatic managing have to gain. However, those structures struggled with heavy-obligation duties. That’s when the chain conveyor began gaining reputation.

By the mid-20th century, chain conveyors had turn out to be important in vehicle vegetation, where cumbersome additives like engines and chassis wanted robust delivery mechanisms. With upgrades in engineering and motor manipulate, the chain conveyor have become extra cutting-edge, adaptable, and easier to keep.

Today, we’re in the technology of Industry 4.0—in which automation, clever sensors, and real-time information are revolutionizing how items flow into. The current-day chain conveyor has advanced with this shift. It’s now covered with Internet of Things (IoT) gadgets, managed via software program software, and monitored for usual overall performance in real time.

In quick, the chain conveyor has gone from a mechanical brute to a clever, tech-powered workhorse—and it’s excellent getting smarter.

How Chain Conveyors Work

Core Components and Mechanism

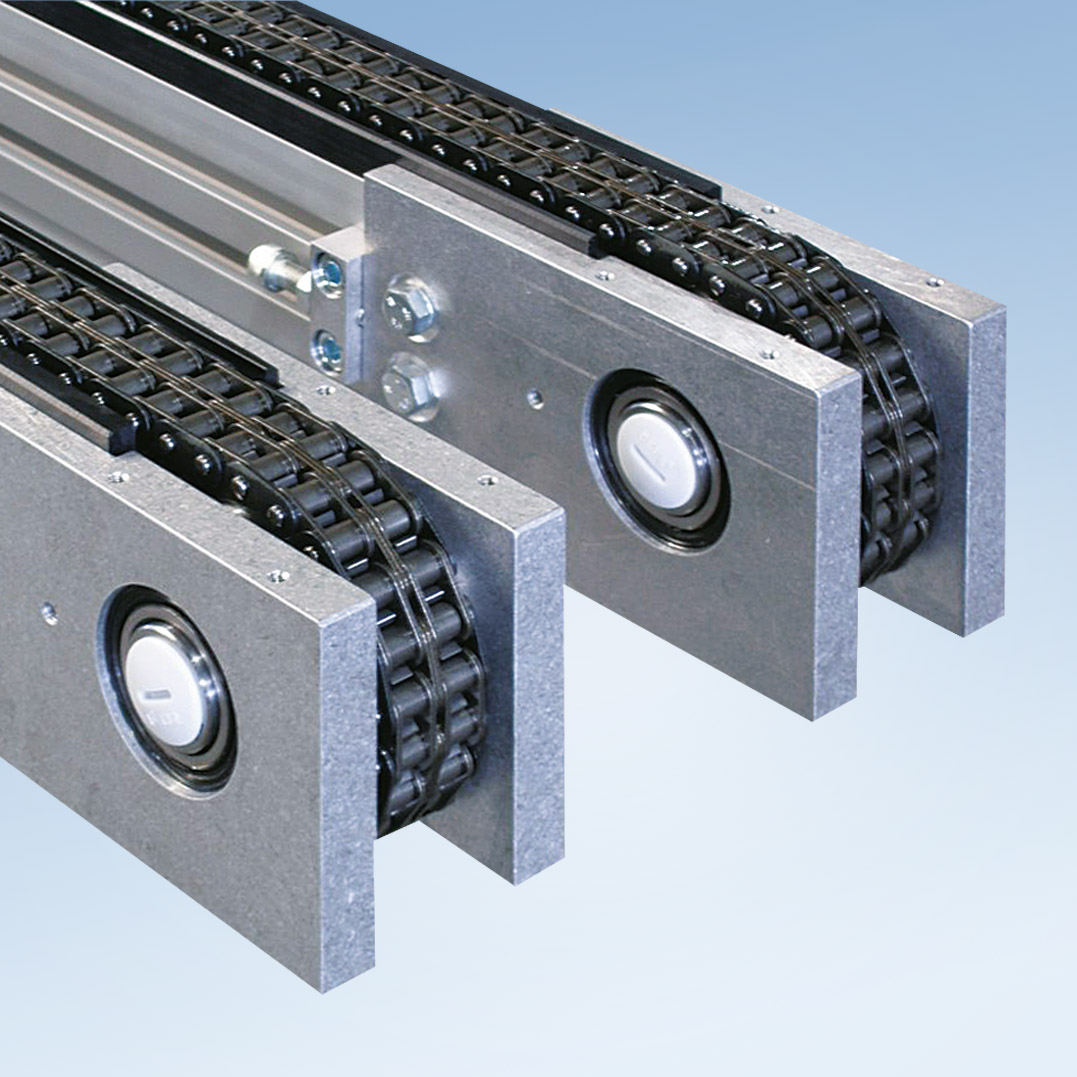

Understanding how a chain conveyor operates starts of evolved with its number one additives. At the coronary heart of it all are the chains—typically made from excessive-grade metal and designed to remaining thru years of damage and tear. These chains are looped around sprockets, which might be in flip associated with a motor. When the motor activates, the sprockets rotate, pulling the chain along a predetermined path.

The load—whether it’s far a metal pallet or a plastic field—rests right now on furniture or slats which is probably set up to the chain. As the chain movements, so does the burden, visiting seamlessly from one phase of a facility to another. In a few systems, rollers are introduced to lessen friction and make movement smoother.

Another important a part of the chain conveyor is the frame, which homes all shifting elements and offers structural guide. Depending on the software, frames may be made from chrome steel (high-quality for easy environments) or powder-lined metal (nice for sturdiness).

Modern chain conveyors are equipped with variable tempo drives, permitting operators to modify motion based on workflow desires. Sensors are frequently blanketed to come upon load presence, prevent the chain at the same time as critical, or cause an alarm in case of blockages.

But what absolutely makes a chain conveyor standout is its ability to keep precision beneath load. Unlike belt structures that might slip or stretch, the chain guarantees that movement is right. That’s important in industries like car or electronics, wherein timing and placement are non-negotiable.

Types of Chain Conveyors

The time period chain conveyor covers a lot of specialized structures, every designed to serve precise operational goals. Here’s a breakdown of the maximum commonplace types:

Slat Chain Conveyors: These have slats (flat plates) connected to the chains, first-rate for transporting heavy or irregularly commonplace gadgets like engine blocks.

Drag Chain Conveyors: Ideal for moving bulk substances like grains, sand, or powders internal a closed channel, regularly seen in agriculture or mining.

Pallet Chain Conveyors: Built to hold pallets loaded with materials through production or warehouse strains.

Overhead Chain Conveyors: These boost masses off the floor, growing greater floor area. They’re a staple in car paint stores and garment dealing with.

Multi-Strand Chain Conveyors: Designed for distributing masses at some point of more than one chains for better weight distribution.

Each form of chain conveyor gives its personal set of benefits. For example, slat chain conveyors are much less complicated to smooth, on the same time as overhead versions store valuable ground region. Regardless of type, the not unusual thread is reliability and ordinary overall performance.

When deciding on a tool, it’s essential to undergo in mind the form of load, surroundings, and throughput expectancies. One of the most important blessings of the chain conveyor tool is that it’s modular—you can combination and in shape additives to create a custom solution tailor-made for your actual goals.

The Rise of Smart Material Handling

The Role of Automation in Modern Logistics

In these day’s high-speed, performance-obsessed industries, automation isn’t a luxury—it’s a want. As e-alternate, mass customization, and global supply chains increase greater complicated, the call for for smart fabric managing answers just like the chain conveyor is skyrocketing.

Why? Because traditional guide coping with absolutely can’t hold up. Modern logistics requires pace, consistency, and real-time information. This is wherein the chain conveyor shines. When protected with automation era—like sensors, PLC structures, and software program software program-pushed controls—a sequence conveyor will become a long way extra than only a mechanical device. It transforms proper right right into a smart, responsive gadget that adapts on the fly.

Imagine a distribution middle wherein products want to be sorted, packed, and shipped within hours of being ordered. Here, the chain conveyor works in fine harmony with barcode scanners, choose-and-place robots, and AI-driven sorting algorithms. It’s speedy, it’s miles specific, and it dramatically reduces human errors.

In production, computerized chain conveyors can collection components precisely as desired for simply-in-time (JIT) manufacturing. This minimizes waste, maximizes productiveness, and cuts operational costs. And allows no longer forget about approximately safety—automated systems lessen the bodily pressure on employees and create cleanser, greater organized workspaces.

The integration of the chain conveyor into automated logistics systems is not just a fashion—it’s the destiny. And it’s a future being built link via manner of link.

Why Chain Conveyors Are Ideal for Smart Handling Systems

The chain conveyor has emerged because of the fact the move-to solution for clever cloth dealing with, and it’s not difficult to peer why. Unlike belt or curler structures, chain conveyors provide a rare mixture of electricity, reliability, and customization that fits flawlessly in the framework of modern automatic environments.

One of the maximum vital advantages is precision manipulate. Because chains don’t stretch or slip like belts, they offer regular motion—a want for robotic packages wherein millimeter accuracy topics. This is particularly essential in meeting lines wherein more than one systems want to be synchronized flawlessly.

Then there’s the strength. A chain conveyor can be tailor-made to more than one paths—horizontal, vertical, curved, or sloped—at the identical time as preserving excessive load capability. It also can be geared up with sensors and IoT modules that deliver actual-time general performance data to manipulate systems. This lets in for predictive protection, performance assessment, and immediately response to any problem—all part of the clever manufacturing unit imaginative and prescient.

From a price attitude, clever-enabled chain conveyors lessen downtime and make bigger lifespan via the usage of alerting operators to wear and tear earlier than a breakdown takes area. Over time, this proactive technique saves masses of dollars and maintains operations walking with out problems.

When mixed with AI and gadget getting to know, a chain conveyor may even take a look at from its surroundings, optimizing routes, adjusting speeds, and adapting to new workflows. It’s no longer certainly shifting materials—it’s moving into the destiny.

Benefits of Using Chain Conveyors

Durability and Load Capacity

If there’s one word that truly defines the chain conveyor, it’s durability. Built with heavy-obligation metallic chains, strong frames, and excessive-torque automobiles, chain conveyors are engineered to thrive in the toughest environments. Whether you are coping with sharp metal parts in a fabrication hold or wet crates in a beverage bottling plant, the chain conveyor should now not absolutely live to inform the story—it excels.

Let’s talk numbers. While a sizeable belt conveyor could possibly address 100–200 kilos in line with foot, a sequence conveyor can convey lots. This makes it the preferred preference for transporting large, bulky, or dense substances along with automobile additives, timber, or business gadget.

Another motive for their lengthy lifespan is the minimum put on and tear on additives. Unlike belts which could fray or rollers that get jammed, chains hold their form and integrity over time. Even in harsh environments concerning moisture, chemical substances, or abrasive particles, a nicely maintained chain conveyor continues shifting.

The load balance furnished via a series conveyor moreover enhances product safety. Items sit down securely on the chain’s attachments, lowering the hazard of slipping, tilting, or falling. That stability makes a big difference while coping with fragile devices, immoderate-value components, or uncommon-original devices.

Bottom line? If your operation demands power, durability, and minimal downtime, a series conveyor can offer on all fronts.

Versatility Across Industries

The chain conveyor is a chameleon in the global of business corporation automation. Its versatility allows it to be customized for certainly any enterprise, from meals processing to heavy production. This adaptability is definitely one of the maximum crucial reasons why it’s come to be the spine of clever cloth coping with at some stage in the globe.

In the car location, chain conveyors float everything from axles to chassis through awesome ranges of manufacturing. Their functionality to cope with heavy hundreds even as keeping precision is unequalled. In warehousing and logistics, they function immoderate-tempo sortation structures, transporting objects from one dock to each other without bottlenecks.

In the meals and beverage agency, stainless-steel chain conveyors are utilized in environments in which hygiene is critical. Their easy-to-smooth surfaces and excessive resistance to corrosion lead them to first-rate for transporting bottled drinks, canned gadgets, and packaged factors.

The electronics place furthermore blessings from chain conveyors. When assembling circuit boards or sensitive gadgets, precision is paramount. The stability and accuracy of a chain conveyor help make sure that every detail is in the proper vicinity on the right time.

Even in immoderate environments like mining or chemical processing, heavy-responsibility drag chain conveyors are used to transport raw substances beneath immoderate pressure and temperature.

Simply placed, no matter your enterprise, there’s a chain conveyor device that may be tailor-made to meet your proper desires.

Common Applications of Chain Conveyors

Manufacturing and Assembly Lines

In the sector of manufacturing, timing and consistency are everything. That’s why the chain conveyor is a staple in assembly traces throughout industries. Whether constructing automobiles, home machine, or electronics, those structures are designed to streamline operations, reduce waste, and growth output.

Picture a automobile assembly plant: engines, transmissions, and chassis go with the flow along a synchronized gadget, preventing exactly at each station for set up, inspection, or portray. Without the chain conveyor, maintaining this stage of precision and general performance is probably nearly now not possible.

What makes the chain conveyor exceptional proper right here is its capability to deal with wonderful degrees of a product’s lifecycle at the identical line. Need to pause for wonderful checks? Sensors can halt the conveyor at exactly the proper second. Need to transport a 1/2-ton engine block? The chain conveyor handles it with out problems.

And with modular designs, producers can fast reconfigure or increase the gadget to comply to new products or workflows. This flexibility is critical in nowadays’s speedy-changing manufacturing environments.

Food and Beverage Industry

The meals and beverage organization poses specific worrying situations for fabric managing—strict hygiene standards, moist situations, and rapid-paced operations. The chain conveyor rises to those stressful situations with systems crafted from stainless steel, designed to stand as a lot as corrosion and permit easy cleaning.

These conveyors are generally positioned in bottling flora, canning traces, and bakery manufacturing centers. With their easy, non-stop motion, chain conveyors transport delicate merchandise without bruising or damaging them—vital for perishable gadgets.

Additionally, their layout facilitates save you the accumulation of particles, reducing contamination dangers. When combined with automatic wash-down structures and antimicrobial additives, chain conveyors come to be critical in sanitary environments.

Whether it’s transporting crates of juice, sealed snack packages, or frozen objects, a sequence conveyor guarantees products waft efficaciously and appropriately from begin to finish.

Customization and Integration Capabilities

Modular Design for Scalability

One of the first-class strengths of the chain conveyor is its modular design. This approach that it’s no longer a one-size-suits-all device—a ways from it. Instead, chain conveyors can be designed, built, and modified in a modular style to healthful the right wishes of your facility. This makes them quite scalable, whether or not or not or no longer you’re running a small workshop or a sprawling distribution middle.

What does “modular” without a doubt mean proper proper here? It way that one in each of a kind additives—chains, sprockets, pressure devices, frames, sensors, and extra—can be decided on and organized in a manner that suits your precise workflow. Need to add a further production station? Simply increase the conveyor with the useful aid of placing a latest module. Need to reroute your product flow? Just reconfigure the layout with pre-designed curved or sloped sections.

The chain conveyor grows together along with your business. Start small and scale up. Unlike many traditional conveyor systems, you don’t must tear it down and begin over at the identical time as you extend—you virtually upload on. That saves time, cash, and pretty some complications.

This scalability is especially essential in industries that experience seasonal surges or fast boom. A properly-planned chain conveyor tool can be the foundation of your operations, bendy sufficient to conform as your desires trade.

Integrating with Robotics and IoT

In these day’s smart factories, integration is the whole thing. And the chain conveyor is one of the most integration-great systems to be had. Thanks to open design standards and standardized protocols, chain conveyors can be with out trouble linked with robotics, IoT gadgets, and centralized manipulate systems.

Picture this: as a product movements alongside the chain conveyor, sensors encounter its feature and feed this facts to a robot arm. The robot then is aware about precisely on the same time as and where to seize, vicinity, or check the object. That form of coordination is only feasible even as the conveyor itself is wise—and the chain conveyor suits the invoice.

IoT integration method that every difficulty of the conveyor can be monitored in real time. From motor temperature to chain tension, clever sensors accumulate standard overall overall performance statistics and ship it to a vital dashboard. This permits managers to make informed picks on safety, upgrades, or operational changes.

And let’s not neglect about device studying. When related to AI software, a series conveyor tool can studies usage patterns and are awaiting failures in advance than they seem. That’s predictive protection in motion—lowering fees and stopping unexpected downtime.

When your conveyor tool is hooked up, communicative, and clever, your entire operation will become greater agile. The chain conveyor isn’t sincerely a chunk of machine—it’s a group player inside the digital transformation of industry.

Comparing Chain Conveyors with Other Conveyor Systems

Chain vs Belt Conveyors

Let’s talk comparisons. At a glance, belt conveyors and chain conveyors can also look comparable, but they serve very one-of-a-type roles. A belt conveyor makes use of a continuous loop of cloth to move merchandise. It’s exquisite for mild-weight or sensitive devices—anticipate small packing containers, packaged elements, or consumer objects.

In assessment, a series conveyor is all approximately energy and sturdiness. It uses interlinked metallic chains that could haul big hundreds with out breaking a sweat. This makes chain conveyors the smooth desire for industries like car, steel manufacturing, or heavy logistics.

Another distinction is protection. Belts can put on out, stretch, or fray—in particular in immoderate-friction or harsh environments. Chains, then again, are built to remaining. They require lubrication and alignment checks but are some distance extra strong over the long term.

Also, permit’s talk about flexibility. While belts are constrained to usually without delay-line moves, chain conveyors can navigate curves, inclines, and declines with out slipping. That makes them extra flexible in layout format, specifically in multi-degree centers.

In summary, in case your application wishes energy, flexibility, and prolonged-time period reliability, the chain conveyor is the superior preference.

Chain vs Roller Conveyors

Now allows compare chain conveyors with curler conveyors. Roller systems use a sequence of spinning cylinders to transport devices, each via gravity or motor energy. They’re easy, fee-effective, and super for transferring boxes, totes, or flat-bottomed packing containers.

However, curler conveyors war with heavy or oddly shaped loads. That’s wherein the chain conveyor dominates. It can deliver things that rollers can’t—like pallets, racks, or components that need stable placement.

Another gain of the chain conveyor is motion manipulate. Because rollers can slip or accumulate friction, they’re not quality for applications that require particular timing or stopping at genuine places. A chain conveyor, but, gives precise start-save you functionality, which is important for robotic integration and meeting work.

Also, preserve in thoughts the noise and wear element. Roller conveyors can end up noisy over the years, mainly if bearings put on out. Chain conveyors, on the identical time as potentially noisy without proper lubrication, generally have a tendency to function extra usually beneath load.

Each device has its area, but for smart, automatic, immoderate-load environments, the chain conveyor offers the higher prolonged-term value and reliability.

Maintenance and Longevity

Preventive Maintenance Tips

A chain conveyor is a rugged machine, however like several mechanical tool, it thrives with a hint TLC. Implementing a preventive upkeep regular is the nice way to boom its existence, reduce downtime, and hold top performance.

Start with regular inspections. Weekly seen exams can entice early signs and symptoms of harm—like loose chains, abnormal noise, or misaligned sprockets. Make high quality all safety guards are intact and functioning. Lubrication is important. Keep the chains properly-oiled to prevent friction damage and boom lifespan.

Next, show chain tension. If a sequence turns into too unfastened or too tight, it is able to reason choppy put on or maybe snap below strain. Many contemporary chain conveyors include anxiety indicators or automated tensioning systems to simplify this mission.

Don’t forget about the motor and pressure devices. Check electric powered connections, search for overheating, and take a look at emergency prevent mechanisms often. Replace worn-out components earlier than they fail to avoid expensive breakdowns.

By scheduling monthly deep safety and retaining a detailed logbook, you’ll make certain your chain conveyor continues running like a properly-oiled tool—actually.

Common Issues and How to Fix Them

Even the excellent chain conveyor can run into problem now and then. But most problems are preventable or without problem regular with a piece information.

Common Issue #1: Chain Misalignment

Symptoms: Uneven motion, jerking, or loud clanking.

Fix: Realign the sprockets and take a look at for bent body components.

Common Issue #2: Chain Wear or Elongation

Symptoms: Loose chains, reduced usual normal performance.

Fix: Replace worn chains and undergo in thoughts upgrading to put on-resistant substances.

Common Issue #3: Motor Overheating

Symptoms: Burning smell, shutdowns, or decreased tempo.

Fix: Check air flow, lubricate bearings, and make certain correct voltage supply.

Common Issue #4: Excessive Noise

Symptoms: Grinding, damn, or squealing.

Fix: Lubricate all transferring components, tighten loose bolts, and look into bearings.

Common Issue #5: Material Jams

Symptoms: Conveyor stops or jerks unexpectedly.

Fix: Clear obstructions, set up jam sensors, and optimize cloth go with the flow fees.

Understanding those troubles—and the way to restoration them—can prevent a ton of cash and stress. With the proper interest, your chain conveyor will serve you faithfully for many years.

Environmental and Safety Advantages

Energy Efficiency in Modern Systems

It’s clean to expect that a series conveyor, with its heavy-responsibility assemble and rugged power, may want to guzzle power like there’s no the following day. But contemporary engineering tells a unique tale. Today’s chain conveyor systems are smarter and additional strength-inexperienced than ever earlier than.

Thanks to improvements in motor technology, chain conveyors now perform with variable frequency drives (VFDs). These drives allow operators to modify motor tempo and torque counting on load necessities. That approach no more whole-throttle power waste whilst simplest half of the functionality is in use. Instead, the conveyor makes use of absolutely the right amount of energy for the project available.

Also, regenerative braking systems have come to be a undertaking-changer. When a series conveyor slows down or stops, in region of dissipating electricity as heat, it captures and shops that electricity for future use. This eco-aware innovation can result in massive power economic savings, specially in excessive-quantity environments.

Additionally, light-weight substances, precision bearings, and espresso-friction coatings all make contributions to reduced energy consumption. So, at the same time as chain conveyors may additionally moreover moreover look like the beasts of the commercial international, they’re turning into more like hybrid athletes—robust, however tremendously inexperienced.

And allows now not neglect about the placement of automation. With clever sensors tracking ordinary general overall performance, chain conveyors can be programmed to close down or enter standby mode at the same time as now not in use. This reduces idle electricity draw and allows lessen operational fees without affecting productiveness.

The shift toward strength-green chain conveyor systems shows a broader style in commercial sustainability. It’s now not just about transferring substances—it’s far approximately transferring ahead with responsibility.

Safety Features and Worker Protection

Safety inside the workplace is non-negotiable, and the chain conveyor plays a vital role in growing solid commercial organization environments. Far from being a chance, modern-day chain conveyors are designed with more than one protection abilities to shield human beings and ensure clean operations.

To begin, most chain conveyor systems embody safety guards and covers that save you accidental contact with shifting chains or sprockets. These limitations are vital for stopping injuries, particularly in busy facilities in which human-device interplay is commonplace.

Emergency prevent structures are some other middle characteristic. Strategically positioned e-save you buttons along the conveyor allow human beings to halt the whole line at once in case of an emergency. Some superior structures even function rope-pull or wi-fi e-stops for greater flexibility.

Then there’s overload protection. Modern chain conveyors are prepared with torque limiters and overload sensors that come across while the machine is sporting more than it need to. If triggered, the device each slows down or shuts off to save you damage or harm.

Anti-jam sensors and automated close-off mechanisms additionally play a huge issue in worker safety. If an object receives lodged within the conveyor, the machine detects the obstruction and prevents before anybody desires to intrude manually.

Training and ergonomic layout round out the protection profile. Because chain conveyors take away the want for manual lifting or pushing of heavy gadgets, they reduce the danger of musculoskeletal injuries. Workers spend a lot less time straining and greater time handling operations effectively and well.

The bottom line? A properly-designed chain conveyor doesn’t simply skip merchandise—it builds a greater stable, more reliable paintings surroundings.

Future of Chain Conveyors in Industry 4.0

Predictive Analytics and Smart Monitoring

The fourth employer revolution—also called Industry 4.0—is all about clever production, real-time facts, and automation. And yes, the chain conveyor is proper in the thick of it, evolving into an smart asset internal virtual ecosystems.

Predictive analytics is one of the most interesting applications. Through embedded sensors and IoT connectivity, a series conveyor can collect statistics on vibration, temperature, chain tension, and motor general performance. This data is then analyzed the use of AI algorithms to are anticipating on the same time as a factor would probably fail or even as renovation is needed.

Instead of reacting to troubles, operators can now prevent them. This reduces unplanned downtime, cuts protection fees, and extends the life of the entire device. Imagine statistics that a sprocket will fail in forty hours—in advance than it actually takes vicinity. That’s the energy of predictive upkeep in a clever chain conveyor machine.

Smart monitoring doesn’t prevent at protection. It moreover offers insights into operational average performance. Managers can view dashboards that display how lengthy the chain conveyor is energetic, how a lot load it’s carrying, and the way it plays over the years. With this statistics, they could optimize workflows, reduce energy utilization, and allocate assets extra efficaciously.

This form of intelligence transforms the chain conveyor from a passive device to an energetic player in manufacturing technique. It doesn’t sincerely drift materials anymore—it gives you insights, improves uptime, and drives smarter choices.

Chain Conveyors in Sustainable Operations

Sustainability is greater than a buzzword—it’s a business enterprise important. Companies are underneath developing pressure to reduce their carbon footprint, and the chain conveyor is proving to be an surprising best friend in this venture.

For starters, long lasting manufacturing method chain conveyors final longer and require fewer replacements. That reduces the environmental charge of producing, delivery, and installing new structures. Fewer breakdowns additionally propose fewer emergency provider calls and much a great deal less wasted power.

As we said earlier, energy-inexperienced motors, VFDs, and regenerative braking systems all make contributions to a greener operation. Some systems are even powered via renewable power assets, making the chain conveyor a relevant parent in inexperienced factories.

Recyclability is each different advantage. At the cease of its lifecycle, most elements of a sequence conveyor—from the steel chains to the motor casings—can be recycled. This contributes to a spherical economic gadget wherein materials are reused in preference to discarded.

And allows no longer forget about approximately adaptability. Because chain conveyors can be reconfigured and prolonged, businesses can preserve the use of them as their goals exchange, heading off the waste of buying completely new systems whenever they make bigger or pivot.

In the contemporary industrial corporation panorama, the chain conveyor is turning into a photograph of sustainable improvement—one hyperlink at a time.

Conclusion

The chain conveyor isn’t clearly an business organization relic—it’s a forward-questioning, powerhouse tool that’s evolving to meet the desires of modern, clever, and sustainable operations. From its rugged beginnings in the automobile employer to its present role in excessive-tech factories and inexperienced warehouses, the chain conveyor has established its rate time and again.

It gives electricity, precision, and versatility. It supports automation, integrates with AI and IoT, and permits lessen power intake and operational charges. Most importantly, it adapts—evolving at the aspect of your enterprise as you scale and innovate.

So in case you’re making plans your subsequent large industrial improve or designing a today’s manufacturing line, don’t overlook approximately the chain conveyor. It’s now not clearly moving materials—it’s powering the destiny of clever fabric managing.

FAQs

1.What materials are super moved with a series conveyor?

Chain conveyors are ideal for heavy, cumbersome, or irregularly fashioned substances. This consists of pallets, engine components, crates, device, or maybe grain or powder at the same time as using drag chain designs.

2.Are chain conveyors suitable for cleanroom environments?

Yes, with the right configuration. Stainless metallic chain conveyors are often utilized in meals, pharmaceutical, and cleanroom programs wherein hygiene and infection control are crucial.

3.How prolonged does an ordinary chain conveyor final?

With right safety, a remarkable chain conveyor can final 15 to 20 years or extra. Many systems are modular and upgradable, extending their lifespan even similarly.

4.Can chain conveyors be utilized in outside settings?

Absolutely. Chain conveyors designed for outdoor use are constructed with corrosion-resistant substances and sealed components to face up to climate and temperature adjustments.

5.How does a chain conveyor decorate workflow overall performance?

By automating the shipping of heavy or complex masses, chain conveyors reduce manual hard work, accelerate production, and make sure precise timing—specifically in automatic and robotic environments.