Introduction to Coated Timing Belts

What Are Coated Timing Belts?

When it involves precision in motion systems, included timing belts are an engineering surprise. These belts aren’t virtually regular strength belts; they’re mainly designed with coatings—most importantly silicone—to offer extra strength, grip, and durability. Think of them due to the fact the upgraded, immoderate-ordinary overall performance variations of the conventional timing belts carried out in a massive style of industries.

At the center, blanketed timing belts are made from rubber or polyurethane substances, however the game-changer is the outer coating. Silicone coating, specifically, offers a full-size degree of sturdiness, chemical resistance, and normal traditional performance flexibility. Whether you’re walking a immoderate-pace manufacturing conveyor or an vehicle camshaft, a lined timing belt can ensure smoother, greater inexperienced trendy preferred overall performance.

These belts feature enamel profiles that mesh precisely with matching pulleys. The coating lets in reduce placed on and tear on both the belt and the pulley, offering a more sustainable, lengthy-time period solution. Furthermore, included timing belts are designed to function silently, without troubles, and with minimal protection, making them best for industries wherein precision and cleanliness are paramount.

Why the Shift Toward Silicone Coatings?

Silicone isn’t simplest a advertising and advertising buzzword—it’s far revolutionizing the manner timing belts are applied in current device. The shift to silicone-protected versions came from the want for substances that would manipulate excessive environments. Traditional belts frequently warfare in situations regarding excessive heat, cold, or chemical publicity. That’s in which silicone steps in because the advanced possibility.

Silicone has an exquisite ability to hold its houses at some point of a huge temperature variety, typically from -60°C to 230°C. It’s non-reactive, flexible, and notably evidence in the route of UV rays and oxidation. These dispositions make protected timing belts with silicone coatings essential in environments like food processing plants, car engines, and cleanroom manufacturing.

Moreover, silicone coatings offer a persevering with, non-stick floor. This substantially reduces the accumulation of dirt, grease, or debris—common problems in older belt systems. So, while a enterprise corporation is looking for a solution that gives no longer first-class ordinary normal overall performance but also hygiene and durability, lined timing belts with silicone come to be the circulate-to desire.

Core Materials Used in Coated Timing Belts

The Role of Rubber in Traditional Belts

Rubber has been a staple in timing belt manufacturing for many years. Its affordability and wonderful placed on Coated timing belts resistance made it the default fabric for plenty manufacturers. Standard rubber belts regularly encompass fibers which incorporates fiberglass or Kevlar to feature tensile electricity, preventing stretching and enhancing durability.

However, whilst rubber served nicely in its time, it isn’t without boundaries. It has an inclination to degrade in immoderate-temperature environments and is susceptible to chemical attacks. In addition, rubber can take in oils and moisture, vital to potential slippage and reduced effectiveness. These obstacles pushed engineers to discover better, extra superior alternatives—ushering in the age of covered timing belts.

Despite the ones drawbacks, rubber even though serves a cause. In low-call for programs or non-essential environments, traditional rubber belts can be a price-powerful answer. But on the equal time as regular trendy performance, reliability, and hygiene depend, protected timing belts, especially those more ideal with silicone, stand a class apart.

Silicone: The Star of Modern Belt Coatings

Silicone’s function inside the worldwide of protected timing belts can’t be overstated. It transforms a ultra-modern belt proper proper proper into a excessive-everyday performance problem able to withstanding rigorous operational needs. First off, silicone’s temperature resistance guarantees that the belt continues its elasticity and common overall performance trends even in harsh thermal situations.

This is particularly beneficial in industries like baking or car manufacturing, in which device can acquire fantastically immoderate temperatures. Moreover, silicone is surely non-stick. This assets is vital for stopping assemble-up of materials like flour, oil, or pharmaceutical powders—ensuring that tool stays clean and powerful with minimum downtime.

Another benefit is chemical resistance. Silicone-blanketed belts can address publicity to solvents, oils, acids, and cleansing marketers without degrading. This makes blanketed timing belts exceptional for meals-grade and pharmaceutical packages wherein sanitation is non-negotiable.

From a mechanical point of view, silicone offers better grip and flexibility, decreasing the threat of slippage. It additionally creates a softer, greater pliable touch floor that’s slight on the pulley machine, lowering positioned on and making sure longer existence for each components.

Key Benefits of Silicone-Coated Timing Belts

Enhanced Durability and Lifespan

The primary draw of included timing belts is their wonderful sturdiness. Silicone coatings notably expand the lifespan of the belt, in particular in intense situations wherein well-known belts would possibly rapid degrade. In a immoderate-friction, immoderate-velocity surroundings, conventional belts typically have a propensity to wear down faster due to warmness and mechanical strain.

Silicone’s functionality to face as a great deal as each thermal degradation and fabric fatigue method that blanketed timing belts can run for tens of masses of cycles with out big placed on. This extended issuer lifestyles interprets to lower operational expenses, lots much much less frequent replacements, and fewer maintenance interruptions.

Think of those belts as an investment. While the in advance charge is probably barely better than conventional belts, the reduced protection and downtime can keep a business enterprise huge sums over the years. Moreover, plenty tons less not unusual belt adjustments imply fewer opportunities for installation mistakes, decreasing the risk of mechanical screw ups.

Superior Temperature Resistance

Temperature extremes can wreak havoc on conventional timing belts. Whether it’s an business oven or a freezing warehouse, overall performance frequently drops at the identical time because the belts are pushed past their consolation region. But protected timing belts with silicone thrive in such extremes.

Silicone continues its shape and elasticity in the course of a huge temperature variety, making it a top notch desire for any application in which heat or bloodless is probably a problem. Unlike rubber, that could crack or end up brittle on the same time as cold, or melt and degrade at the equal time as warm, silicone-coated belts hold everyday typical performance throughout.

This is particularly beneficial in programs that require both heating and cooling cycles. A unmarried covered timing belt can stay mounted for every tiers, eliminating the want for common belt changes due to temperature barriers.

Exceptional Flexibility and Grip

In applications requiring specific synchronization, belt slippage is the enemy. That’s in which the silicone coating in truth shines. Its unique texture and pliability enhance grip with out damaging the pulleys. This superior traction guarantees that blanketed timing belts can transmit torque extra correctly, reducing energy loss.

Flexibility is a few exceptional standout gain. Silicone-covered belts can bend and twist over smaller pulley diameters with out cracking or losing structural integrity. This makes them ideal for compact equipment wherein vicinity is restrained, yet average overall performance can’t be compromised.

The more wonderful grip moreover manner higher acceleration and deceleration manage, particularly in automation systems wherein timing and responsiveness are essential. In essence, silicone doesn’t definitely coat the belt—it transforms it.

Applications Across Industries

Automotive Advancements

In the fast-evolving worldwide of automobile engineering, blanketed timing belts have placed their area beneath the hood—certainly. These belts are pivotal in synchronizing the rotation of the crankshaft and camshaft, making sure that the engine’s valves open and close to on the right instances. With silicone coating, they carry about unrivaled reliability and precision.

Automotive engines often perform at high temperatures and underneath extreme mechanical hundreds. Silicone-included variations are high-quality right right right right here because of the fact they’re able to face up to intense warm temperature and friction with out stretching or sporting out. This effects in fewer timing mistakes, less engine noise, and appreciably longer belt life.

Another benefit is reduced safety. Traditional belts require not unusual inspections and replacements. Coated timing belts, especially silicone-protected ones, can circulate drastically longer and now not the use of a need opportunity, presenting a better pass decrease back on investment for both manufacturers and vehicle owners. With electric powered powered powered cars on the rise, the ones belts are also being integrated into cooling systems and powertrain designs that name for absolute precision.

Food Processing Industry

Cleanliness, non-infection, and high everyday overall overall performance—the ones are the critical wishes of food-grade gadget. That’s why coated timing belts have come to be ultra-present day in food processing strains. The silicone ground is non-toxic, odorless, and proof against bacterial boom, making it notable for direct meals touch applications.

From dough sheeting to chocolate enrobing, those belts provide a non-stick, clean, and hygienic ground that minimizes residue and product waste. Because they may resist rigorous cleansing techniques, which consist of publicity to steam, warm water, and aggressive disinfectants, they’re both sensible and compliant with strict food protection requirements.

Silicone-included belts moreover lessen belt replacements because of located on and infection, a vast gain for twenty-4/7 meals production facilities. Many are licensed under FDA and EU meals-grade tips, making them now not only safe however additionally organisation-authorized. In quick, coated timing belts help corporations preserve food steady and manufacturing strains taking walks with out difficulty.

Medical and Pharmaceutical Equipment

In environments wherein cleanliness is non-negotiable, covered timing belts display their charge yet again. Pharmaceutical and clinical industries depend upon pretty sanitized environments, regularly known as cleanrooms, in which even the tiniest contaminant may be catastrophic.

Silicone’s non-porous floor and resistance to chemical disinfectants make it high-quality for such makes use of. Whether it’s in a tablet-packaging line, a surgical tool assembly device, or diagnostic device, silicone-included timing belts decrease contamination dangers. They function silently, reduce vibrations, and supply the regular movement required thru using using touchy scientific system.

In addition, the ones belts frequently function anti-static houses that help avoid electrostatic discharge (ESD)—a intense problem round touchy electronic scientific gadgets. For essential tool that must carry out with out fail, covered timing belts are a cornerstone element, providing the high-quality aggregate of cleanliness, precision, and reliability.

How Coated Timing Belts Improve Efficiency

Reduced Downtime and Maintenance

Operational downtime is one of the maximum high-priced issues in any employer. Every time a device halts for maintenance or belt replacements, productivity takes a fulfillment. Enter lined timing belts, which is probably engineered for sturdiness and low-protection operation.

Because silicone coatings are proof in opposition to warmth, chemical compounds, and friction, they experience lots a lot less located on as compared to conventional belts. This resilience results in fewer breakdowns, lowering the want for commonplace belt tests or emergency replacements. These belts moreover do no longer want lubrication, in assessment to chains or a few rubber belts, removing an entire layer of protection.

Over time, the charge savings are big. Imagine a manufacturing line that quality wishes its belts modified as quick as a year rather of each few months. That’s no longer clearly reduced downtime—it’s far a soar in operational overall performance. Businesses can invest the ones stored hours and assets another time into production, innovation, and increase.

Boosting Mechanical Accuracy

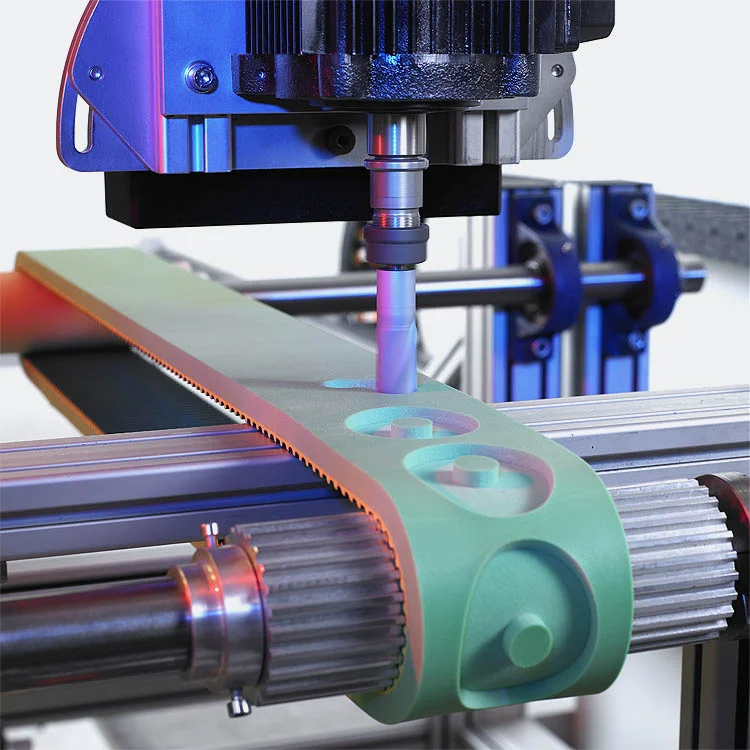

Precision is the whole lot in current-day gadget. From robot palms to packaging machines, even a small take away in belt timing can result in product defects or system malfunction. That’s wherein included timing belts are available with their superior synchronization competencies.

Thanks to their superior grip and minimum elongation, the ones belts hold quality timing among the usage of and driven additives. This is crucial in applications like three-D printing, clinical dosing machines, and vehicle timing systems in which cut up-second accuracy is vital.

Silicone-coated belts, specially, have low tolerance for dimensional alternate, which means that that they hold their form and tension even after prolonged use. This permits for normally accurate operation at some stage in tens of loads of cycles. The stop give up result? Fewer product defects, extra patron pleasure, and more potent brand reliability.

Minimizing Slippage and Power Loss

One of the worst culprits within the back of energy inefficiencies in mechanical systems is slippage. Traditional belts, in particular in excessive-tempo or greasy environments, can lose grip and decrease torque transfer. Not so with protected timing belts.

The silicone coating complements friction houses a few of the belt and the pulley. It creates a easy however grippy ground that “locks in” to the teeth of the pulley with minimum electricity loss. This tight engagement ensures that energy is transmitted with immoderate performance from the motor to the mechanical additives.

This typical performance translates at once to decrease energy consumption. When automobiles don’t want to trap up on slippage or misalignment, they run smoother and eat a great deal plenty tons less strength. Over time, this decreased power draw can considerably lower operational expenses, mainly in massive-scale operations.

Comparison with Other Types of Timing Belts

Rubber vs. Silicone-Coated Belts

Rubber timing belts have served industries well, but they’ve got limitations. They’re liable to cracking, put on quicker beneath immoderate temperatures, and require everyday protection. On the alternative hand, coated timing belts, in particular human beings with silicone layers, increase not unusual established overall performance necessities in the course of the board.

Rubber belts often take in oils and moisture, which can weaken their form and decrease their grip. Silicone, being hydrophobic and non-reactive, continues its integrity even when exposed to harsh conditions. This approach that silicone-protected belts ultimate longer and perform higher in difficult environments.

Noise reduce charge is a few one among a type key distinction. Rubber belts can squeal or vibrate, in particular while misaligned or beneath load. Silicone-lined variations offer whisper-quiet operation, making them high-quality for noise-sensitive areas like laboratories or excessive-forestall production floors.

Cost-sensible, silicone-blanketed belts may have a higher in advance rate, but they offer advanced ROI with the useful aid of the usage of reducing down on renovation and growing opportunity cycles. It’s a smooth win even as not unusual performance and sturdiness are prioritized.

Polyurethane vs. Silicone-Coated Timing Belts

Polyurethane is some one-of-a-kind strong contender inside the timing belt worldwide. Known for its abrasion resistance and structural strain, it’s generally implemented in heavy-load applications. However, on the identical time as you look at it right now to included timing belts with silicone, the variations are clean.

Polyurethane belts are stiffer and plenty much less flexible, which makes them less suitable for packages requiring commonplace bending or compact pulley structures. Silicone-blanketed belts, in evaluation, stay pliable whilst providing superb load-bearing capability. This makes them bendy throughout notable machines.

Where polyurethane shines in abrasion resistance, silicone dominates in temperature and chemical resistance. If your software program application includes warm temperature, steam, or exposure to solvents, lined timing belts with silicone are the better possibility. They’re moreover higher relevant for environments that name for hygiene and non-contaminant surfaces.

Finally, polyurethane belts can end up noisy over time and might require extra noise-dampening solutions. Silicone belts, with their moderate outside, really absorb vibrations and decrease operational noise—a big benefit in masses of programs.

Customization Options Available

Tailored Tooth Profiles

One of the motives why blanketed timing belts are gaining big reputation is their adaptability to precise commercial enterprise necessities. Not all machine is created equal, and that’s in which customization alternatives, like tailored enamel profiles, come into play. Depending on the software, belts may be fabricated with trapezoidal, curvilinear, or changed curvilinear tooth that during form the suitable desires of the pressure device.

Tailored enamel profiles make sure maximum appropriate load distribution, greater excessive quality grip, and minimized backlash. This is specifically important in precision-heavy industries like robotics, CNC machining, and packaging, in which any mild version in belt timing must disrupt complete techniques. Silicone-covered variations take it a step further via presenting superior flexibility and reduced noise at some stage in custom geometries.

Designing a covered timing belt with the right tooth profile is like remarkable-tuning a musical tool—it’s all about harmony some of the additives. This concord outcomes in smoother operation, better energy average performance, and lots a great deal lots less wear on each the belt and the pulley. For companies striving for excellence and reliability, tailor-made belts aren’t a pricey—they’re a need.

Coating Thickness and Surface Finish

Another critical customization detail in lined timing belts is the thickness of the silicone coating and the floor end. These can be adjusted based totally on the form of software program, the volume of infection resistance desired, or the capacity required. Thicker coatings may additionally provide extra protection and durability, on the identical time as thinner coatings hold better pliability and grip.

For instance, in excessive-tempo conveyor systems, a slightly textured ground is probably determined at once to beautify traction and decrease slippage. On the flip element, in medical-grade programs, a in reality-smooth give up guarantees zero particle accumulation and smooth sanitation.

The beauty of silicone as a cloth lies in its versatility. Manufacturers can manage it to fulfill particular dreams with out sacrificing regular time-honored overall performance. And due to the reality every detail subjects while designing excessive-performance belts, having the capability to control coating thickness and surrender makes coated timing belts the most dynamic possibility available in modern-day market.

Anti-Static and Color Coding Options

Static strength may be unstable—no longer really to system, however additionally to people. In touchy industries like electronics manufacturing or cleanroom environments, anti-static houses are a want to. That’s why many included timing belts may be custom designed with anti-static formulations to securely burn up electric powered powered powered expenses.

Additionally, coloration coding is turning into a sought-after characteristic. Different belt colorations can imply unique capabilities, renovation cycles, or ranges of damage. This lets in technicians speedy discover and replace worn belts, decreasing mistakes and enhancing safety.

Whether it’s blue for meals-grade, white for pharmaceutical, or black for heavy-duty applications, shade coding offers a practical and visible layer of average typical overall performance. These small but huge customizations further growth covered timing belts beyond their conventional opposite numbers, turning them into smart, tailor-made answers for each want.

Installation and Maintenance Best Practices

How to Install Seamless Coated Timing Belts

Installation would possibly likely appear straightforward, but doing it wrong can severely shorten the lifespan of a lined timing belt. First topics first—commonly make sure that the belt and pulley are clean and free of any debris. Silicone coatings offer an first-rate grip, however dirt and residue can compromise normal overall performance and motive untimely wear.

During installation, keep away from forcing the belt over the pulley. This can stretch or crack the coating. Instead, adjust the tensioner or remove the pulley (if feasible) to softly area the belt into feature. Make terrific the belt enamel align flawlessly with the pulley grooves to keep away from misalignment and eventual breakdown.

Tension subjects. Over-tightening can stress the silicone coating and increase placed on, at the identical time as underneath-tightening can result in slippage. Always comply with the manufacturer’s recommended anxiety values and use a belt tension gauge if preferred. Regular inspection inside the course of the primary few hours of operation can entice early issues in advance than they emerge as issues.

Proper installation ensures that your protected timing belts carry out at height functionality from day one. And given their functionality for prolonged-time period ordinary general performance, it is able to pay to begin robust.

Tips to Maximize Belt Longevity

Even the remarkable blanketed timing belts want a touch TLC to collect their most lifespan. Routine exams and clever practices may additionally want to make a big difference. Here are some hints:

Keep It Clean: Silicone resists dirt and particles, however regular cleaning with a dry material or approved cleanser permits hold gold general not unusual universal performance.

Inspect Tension Frequently: Over time, pulleys can go along with the go with the flow or get unfastened. Recheck belt tension each few months or as encouraged.

Look for Wear Patterns: Uneven positioned on or fraying may also need to suggest misalignment or overloading. Address those issues in advance than they growth.

Use Matching Pulleys: Always pair your lined timing belts with pulleys that during shape their profile and fabric compatibility. A mismatch can boost up placed on or cause slippage.

Avoid Contaminants: Even even though silicone is evidence closer to many chemical materials, extended publicity to competitive solvents or oils may have an impact on everyday common basic overall performance. Use shielding covers or guards wherein feasible.

These first rate practices ensure that your investment in high-quality, silicone-blanketed belts maintains to pay dividends for destiny years.

Environmental and Safety Benefits

Resistance to Chemical Degradation

One of the standout capabilities of included timing belts is their resistance to harsh chemical substances. In commercial enterprise settings, belts also can come into touch with oils, greases, solvents, and cleansing entrepreneurs—all of which can degrade rubber and superb materials through the years. Silicone, however, stands robust.

The non-reactive nature of silicone manner it acquired’t absorb or damage down at the same time as exposed to maximum chemical substances. This allows the belts to hold their structural integrity and ordinary overall performance even in tough environments. It’s why those belts are frequently the pinnacle preference in chemical processing plant life and pharmaceutical labs.

This resistance furthermore method loads a good deal less not unusual substitute, reducing waste and contributing to a more sustainable operation. Companies striving for inexperienced certifications can with a chunk of good fortune encompass protected timing belts of their method, knowing they provide every ordinary everyday universal overall performance and environmental blessings.

Safe for Cleanroom Use

In cleanrooms, even microscopic particles can bring about infection, tool failure, or compromised products. That’s why included timing belts are more and more utilized in industries like semiconductor production, biotechnology, and pharmaceuticals. Their seamless layout and non-porous silicone coating make certain minimum particle emission.

Moreover, silicone’s natural resistance to microbial boom makes it inherently hygienic. It gained’t harbor micro organism, mould, or fungi, and it is able to face up to regular sterilization with steam, UV mild, or disinfectants. This makes silicone-blanketed belts regular for sterile environments wherein cleanliness is important.

Additionally, anti-static options reduce the risk of electrostatic discharge—a critical characteristic even as operating spherical sensitive electronics or volatile chemical substances. By selecting protected timing belts, groups make certain every product integrity and place of job safety, a win-win in any excessive-tech facility.

Future Trends in Timing Belt Technology

Smart Belts with Embedded Sensors

Technology is all at once evolving, or perhaps a few aspect as seemingly easy as blanketed timing belts is gift technique a digital transformation. Enter smart belts—next-gen timing belts embedded with sensors that display actual-time average performance metrics like anxiety, temperature, vibration, and placed on. These belts can deliver symptoms to a centralized device, contemplating predictive upkeep and decreasing the possibility of sudden breakdowns.

Imagine a manufacturing line wherein a belt detects its private degradation and schedules its opportunity earlier than it fails. That’s not technological know-how fiction—it’s occurring these days. Paired with silicone coating, which already complements lifespan and resistance, those smart protected timing belts take ordinary everyday performance and reliability to new heights.

The integration of IoT (Internet of Things) with commercial enterprise hardware is making operations smarter and leaner. Companies adopting sensor-organized belts can reduce downtime, keep away from pricey protection, and enhance regular device prevalent performance. Expect this fashion to emerge as huge in excessive-tech industries within the coming years.

Eco-Friendly Manufacturing Approaches

Sustainability isn’t non-obligatory—it’s a need. As industries try and reduce their environmental footprint, producers of covered timing belts are following in shape. Eco-high-quality belts crafted from recyclable substances and produced in energy-green techniques are beginning to gain traction.

Silicone coatings, at the identical time as already durable and prolonged-lasting, are being subtle to embody bio-based really absolutely substances or synthesized using greener strategies. Companies also are developing belts with reduced VOC emissions and imparting take-decrease again or recycling programs to decrease business agency waste.

In the future, anticipate to look more upgrades that balance widespread overall performance with planetary duty. For clients, this indicates gaining access to belts that no longer most effective deliver brilliant characteristic but moreover align with sustainability desires—a growing priority for modern-day businesses.

Integration with Automation and Robotics

The destiny of manufacturing lies in automation, and included timing belts are playing a foundational role on this shift. Automated structures require precision, consistency, and coffee safety—3 regions in which silicone-lined belts shine.

From robot arms in automobile factories to computerized pill dispensers in hospitals, timing belts assist energy smooth, synchronized movement. Because they reduce noise, resist chemical materials, and very last longer than conventional belts, they’re specifically precious in excessive-throughput environments.

As automation will become extra advanced, assume lined timing belts to adapt along it—with higher coatings, smarter feedback structures, and custom profiles designed mainly for robotic compatibility. They’re not virtually components anymore—they’re enablers of the future.

Conclusion

Coated timing belts have transcended their precise function as mere movement transfer additives. Thanks to enhancements in cloth era—mainly the usage of silicone coatings—they’ve end up wonderful to innovation at some point of industries. From vehicle to pharmaceuticals, meals processing to cleanrooms, these belts supply unmatched sturdiness, hygiene, typical overall performance, and customization.

Whether you are looking for to reduce safety, enhance precision, or perform in excessive environments, lined timing belts provide an answer that combines conventional reliability with cutting-edge regular overall performance. They are the unsung heroes driving modern-day-day tool—quietly inexperienced, pretty durable, and now smarter than ever.

Investing inside the ones excessive-tech belts isn’t only a clever choice for your machines—it’s a strategic flow into to your whole operation. As industries hold to conform, one aspect is first rate: included timing belts will live on the coronary coronary coronary heart of mechanical innovation.

FAQs

- What makes silicone-coated timing belts superior to traditional belts?

Silicone-protected belts withstand warmth, chemical materials, and placed on better than rubber or polyurethane belts. They ultimate longer, require a whole lot much less safety, and are incredible for hygiene-sensitive applications. - Are included timing belts stable for food processing system?

Yes. Many protected timing belts are FDA and EU-approved for direct meals touch. Silicone coatings are non-toxic, odorless, and smooth to sanitize.

3. Can included timing belts be utilized in excessive-tempo packages?

Absolutely. Their greater grip and resistance to slippage cause them to first-rate for excessive-pace gadget, ensuring correct and synchronized common standard typical overall performance.

4. Do these belts require lubrication?

No. Coated timing belts, specially people with silicone surfaces, perform dry and but keep immoderate wellknown average performance, reducing safety dreams.

. How frequently must coated timing belts be replaced?

This varies thru use, however they commonly very last substantially longer than stylish belts. With right installation and care, they may be able perform for years without opportunity.