Introduction to the Smart Packing Revolution

E-alternate is booming, and inside the back of every lightning-fast transport is an advanced fulfillment technique that is constantly evolving. One unsung hero in this revolution is the sphere packer—a powerful machine or gadget designed to beautify the packing performance in warehouses. Gone are the days of chaotic guide boxing, immoderate packaging substances, and gradual dispatch instances. Today, the smart subject packer is changing the sport, transforming how merchandise are packed, protected, and shipped.

Efficiency isn’t simplest a buzzword in current warehousing—it’s a need. When corporations cope with lots, even millions, of SKUs each day, packing can not be left to risk. That’s in which the container packer steps in, the use of algorithms, tool gaining knowledge of, and precision robotics to choose the first-class field, lessen filler waste, and streamline order success.

Consumers don’t typically see this procedure, but they experience the impact—faster deliveries, nicely-packaged devices, and minimal waste. Businesses, as an alternative, see prolonged throughput, happier customers, and reduced fees. The box packer represents the coronary coronary heart of a greater clever, more responsive deliver chain, and in this newsletter, we’re diving deep into the manner it’s making waves in the warehouse and on the frontlines of e-alternate.

What is a Box Packer?

Definition and Core Functionality

At its center, a box packer is a gadget—guide or automated—that determines the maximum green manner to % merchandise into shipping bins. While it sounds easy, the logistics are relatively complex. A subject packer should don’t forget object period, fragility, box dimensions, order kind, shipping approach, or even branding necessities.

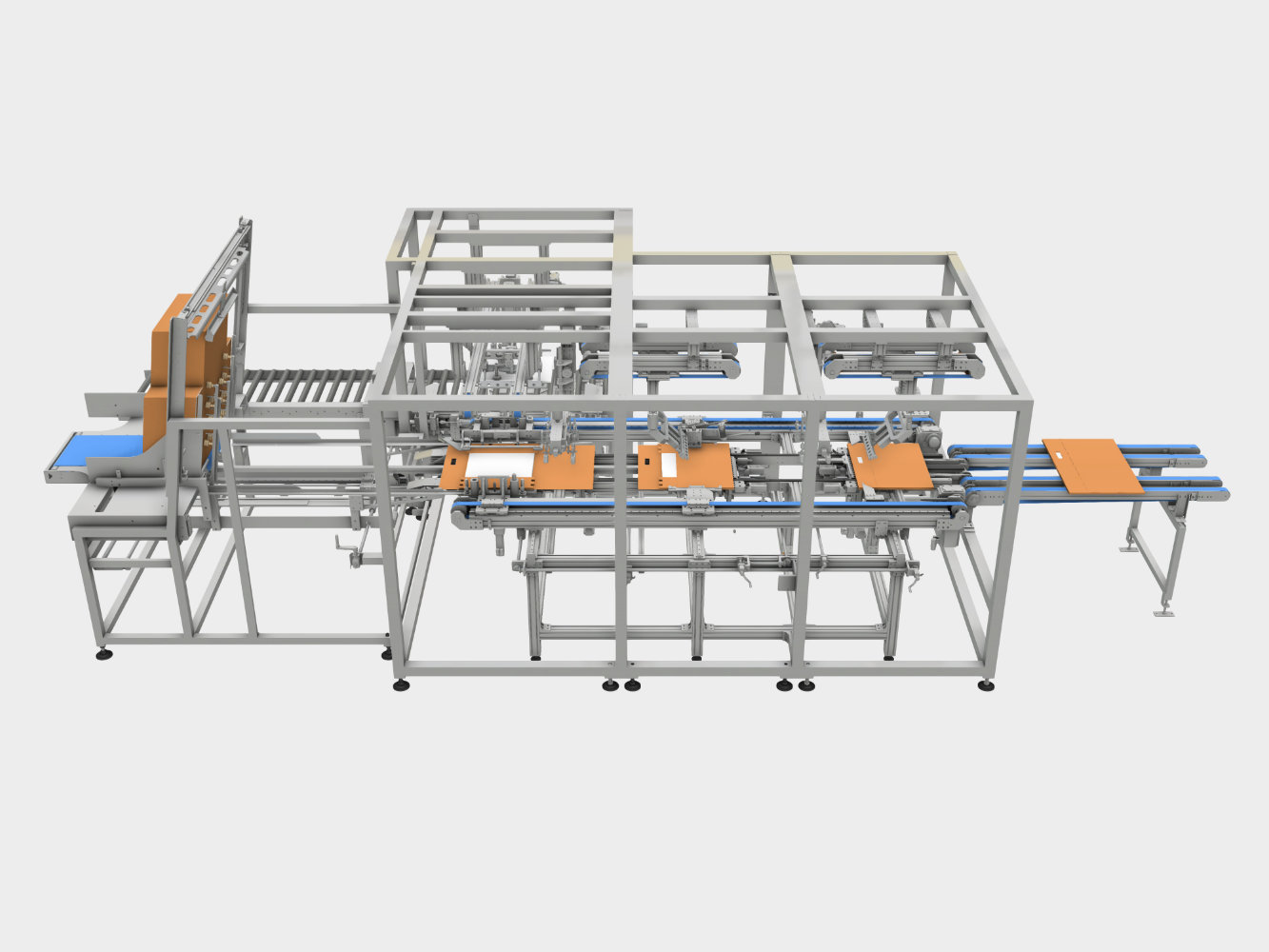

Manual discipline packer stations contain human packers making alternatives at the fly. These systems would possibly still incorporate some tech, like virtual scales and software program application-guided commands. However, the actual magic takes region in automated systems. Advanced field packers use excessive-decision cameras, AI-pushed software, conveyor belts, and robotic palms to turn out to be aware of, type, and box merchandise in real-time.

Some systems even create custom packing containers without delay, flawlessly suited to every order’s dimensions, which reduces void fill and cuts down on delivery prices. Think of it like a 3-D Tetris master, constantly optimizing every shipment for max performance.

Manual vs Automated Box Packer Systems

There’s a large distinction amongst manual and automated field packer setups, and selecting between them relies upon on scale and price range. Manual box packers are greater bendy but additionally more vulnerable to human errors and fatigue. They’re perfect for small agencies with low order volumes or specifically variable product sizes.

Automated container packer structures, on the other hand, shine in high-quantity environments. They paintings tirelessly, don’t need breaks, and can method hundreds of applications consistent with hour with near-perfect accuracy. These structures additionally integrate with warehouse manage structures (WMS), allowing real-time stock monitoring, order verification, and inexperienced load planning.

While automation calls for a better upfront funding, the ROI regularly justifies the value. Companies can considerably lessen labor desires, lower waste, and improve consumer delight way to greater dependable and faster delivery.

The Technology Behind the Box Packer

Software and AI Integration

The backbone of any clever container packer gadget is its software application. This consists of algorithms that analyze the contents of every order and decide which field to use—or whether or no longer to create a cutting-edge one on-name for. These AI-driven systems bear in mind each mind-set: dimensions, weights, fragility, and load urgency.

AI doesn’t simply optimize for length but also for fabric use and price performance. Over time, the machine learns patterns—which include seasonal order kinds or local delivery quirks—and adjusts as a result. This continuous studying makes each subsequent bundle deal a chunk smarter than the final.

In excessive-tech container packer structures, software software additionally syncs with extraordinary achievement generation. Barcode scanners, robot palms, and sorting systems all work in tandem, coordinated through centralized AI software application. The end result? A seamless, lightning-speedy packing line that’s built to scale.

Robotics in Smart Packing

When we recollect robots, we remember humanoid machines doing human responsibilities. But in warehousing, robots are greater specialised—and the sector packer robot is a hold close of its area. These machines don’t walk round; rather, they live rooted in packing stations, executing precise moves to vicinity gadgets, fold bins, and observe tape faster than any human have to.

Advanced robotic subject packers also discover broken objects, incorrect orders, or sub-perfect packing preparations. If a few component’s off, the device indicators a supervisor or reroutes the order to a correction station. This not handiest improves first-class control but additionally dramatically reduces returns and court cases.

The integration of robot hands with suction grippers, facet sensors, and motion control makes the contemporary subject packer a marvel of engineering—able to processing complicated orders with surgical precision.

Benefits of Using a Box Packer in Modern Warehousing

Speed and Accuracy Gains

Speed is king within the world of achievement, and not whatever boosts throughput like a clever field packer. These machines machine hundreds, even lots, of orders each day with minimum errors. In conventional structures, human packers can also deal with 50–one hundred orders consistent with shift. With a clever area packer, that variety can double or triple.

Accuracy is without a doubt as essential. MI’s-packed orders value time, money, and patron consider. A clever container packer doesn’t bet; it calculates. It makes use of precise measurements and actual-time statistics to make certain each order is packed virtually proper. No more outsized bins for tiny gadgets. No more beaten products. Just speedy, correct, smart packing that continues clients coming once more.

Cost Reduction and ROI

While the investment in a field packer may seem steep, the returns are staggering. Labor expenses drop dramatically—specially throughout peak seasons while hiring more assist may be costly and unreliable. Waste bargain additionally performs a main role in fee savings. With more inexperienced packaging, agencies spend tons less on substances and delivery prices.

Additionally, harm-associated returns decrease, which cuts each shipping and restocking prices. Over time, maximum businesses recoup their investment in a container packer internal 12–18 months. For many, it’s a no-brainer.

Space Optimization in Packaging

Ever obtained a tiny item in a large field full of air pillows? That’s inefficient packing—and it’s costly. A field packer solves this with custom or right-sized packing containers, minimizing void region and enhancing pallet density.

In warehouses, optimized packaging manner extra packing containers match into the identical truck or garage rack. This saves on freight, fuel, and warehousing costs. Multiply this in the course of hundreds of shipments, and the monetary financial savings emerge as huge.

How Box Packers Improve E-Commerce Fulfillment

Real-Time Order Customization

One of the biggest wins for e-trade operations is the capacity to customize and personalize orders on the fly. With a smart field packer, corporations can dynamically alter packaging primarily based totally on the real-time facts of each order. Think of it like having a non-public assistant for each single package—understanding exactly what’s in the cart, what form of product is being shipped, and how it wishes to be protected.

For instance, if a customer orders a delicate item at the side of a bulky one, the sector packer makes use of superior AI to decide the maximum steady and most room-inexperienced packing layout. It also selects the nice substances, whether or no longer it is foam inserts, biodegradable fillers, or air cushions. No two orders are the equal, and the cutting-edge subject packer is aware of that. This degree of customization appreciably reduces shipping harm and increases patron satisfaction.

Moreover, seasonal promotions or branded packaging wishes are automatically handled via the system. Want to encompass holiday-themed wrapping or advertising inserts? The container packer integrates those seamlessly. No delays, no confusion—just tailor-made packaging that aligns with organization goals and purchaser expectations.

Minimized Packaging Waste

Sustainability isn’t optional anymore—it’s a want. E-commerce companies are beneath growing strain to reduce their environmental footprint, and the container packer performs a critical position in that mission. By determining the smallest feasible box for every order, it cuts down dramatically on filler substances and cardboard utilization.

Traditional packing often effects in packing containers which can be 30% or even 50% large than important. That’s no longer simply wasteful—it’s highly-priced. With the container packer, every item is snugly and securely packaged, notably lowering packaging waste and carbon emissions. Some structures even use recycled or recyclable substances through default, aligning with eco-aware practices.

Smart container packer structures additionally optimize field decreasing and folding, minimizing leftover scrap within the direction of manufacturing. For organizations trying to meet ESG dreams, adopting a subject packer isn’t just a smart company circulate—it’s an environmental essential.

Enhanced Customer Experience

In the hyper-competitive world of on line shopping for, an first-rate unboxing revel in could make or harm client loyalty. Nobody wants to get preserve of a product in a broken, outsized, or wasteful area. The container packer ensures every order arrives well, securely, and with a cultured attraction which can leave an extended-lasting affect.

When a purchaser sees a subject that fits flawlessly, makes use of minimal waste, and consists of considerate additions like go back commands or thank-you notes, it builds brand trust. It tells the customer, „We care about your experience.“ And the box packer is the within the back of-the-scenes hero making that viable.

Better yet, fewer packing errors imply fewer returns. No one enjoys handling customer service because of damaged items or lacking components. With the accuracy of a smart container packer, the ones issues are reduced to a minimum, growing a easy, frictionless shopping revel in that continues clients coming lower returned.

Industries Transforming Through the Box Packer

Retail and Fashion

The retail and style employer is notoriously fast-paced, with styles and products continuously changing. A field packer enables those businesses hold up with consumer call for via using presenting a packing answer that adapts to special product sizes, shapes, and order complexities.

From folded shirts to sensitive accessories, the field packer handles each object with care. It guarantees minimum wrinkles, prevents harm, or even allows branded packaging that enhances the luxurious revel in many fashion producers strive for. During top seasons like Black Friday or excursion income, the box packer ensures performance with out sacrificing first-rate.

Electronics and Consumer Goods

Electronics are a number of the maximum touchy products to deliver, requiring particular handling and stable packaging. Enter the sphere packer, with its capacity to apply foam inserts, anti-static substances, and perfectly sized packing containers. Whether it is a smartphone, a laptop, or a tough and fast of headphones, the container packer ensures the product arrives intact.

The area packer may even account for add-ons like chargers and manuals, setting them logically within the package deal to avoid confusion. This reduces returns and will increase customer delight in a vicinity in which precision is non-negotiable.

Pharmaceuticals and Healthcare

For the pharmaceutical and healthcare industries, packaging isn’t just about performance—it’s approximately safety and compliance. A discipline packer presents steady, sterile, and compliant packaging that meets regulatory requirements.

Medications, clinical gadgets, and lab kits require cautious dealing with, temperature manipulate, and smooth labeling. The container packer integrates with warehouse management systems to make certain traceability and regulatory documentation, that is important in the ones sectors. It reduces the risk of human mistakes, making sure the right medicinal drug or device reaches the right client or healthcare corporation whenever.

Choosing the Right Box Packer System

Key Features to Consider

Not all subject packer structures are created identical. When searching for the right one, organizations must prioritize flexibility, tempo, fabric compatibility, and integration skills. The notable structures are modular, allowing organizations to start small and make bigger as desired.

Look for a subject packer that helps a couple of area sizes, custom folding, and sensible order scanning. It ought to without problems integrate together with your cutting-edge WMS and ERP systems. User-friendliness is likewise critical—your body of workers should be able to monitor and preserve the gadget without a want a robotics degree.

Don’t neglect protection and monitoring capabilities each. The modern-day subject packer systems can offer tamper-evident packaging, serial tracking, and automated best guarantee. It’s about doing more than certainly boxing—it’s approximately bringing intelligence to each level of the technique.

Vendor Evaluation and Pricing

Choosing the proper supplier is just as essential due to the fact the device itself. A proper box packer employer will offer installation, training, and ongoing help. Check opinions, ask for references, and request a demo to appearance the system in action.

Pricing models range. Some carriers offer outright buy alternatives, on the same time as others provide leasing or subscription-primarily based models. Consider what suits your coins go together with the drift and ROI dreams. Don’t be tempted thru low-fee machines that sacrifice sturdiness or help—you’ll pay extra ultimately.

Scalability and Integration

The quality subject packer machine isn’t simplest for in recent times—it’s for the subsequent 5 to 10 years of growth. That way scalability have to be baked into your selection-making. Can the machine contend with a doubling of your order amount? Does it help worldwide shipping requirements? Can it broaden with you?

Integration is likewise important. Your subject packer must “communicate” in your stock gadget, order manipulate software program program, or maybe your consumer courting management (CRM) gear. The extra associated your gadget, the extra efficient your operations becomes.

Challenges and Limitations of Box Packers

Initial Investment and Setup Time

While the field packer gives easy efficiency and rate economic savings ultimately, the prematurely costs may be daunting—specifically for small to mid-sized organizations. Depending at the complexity and length of the device, initial investments can variety from tens of plenty to numerous hundred thousand bucks. This includes no longer certainly the hardware however additionally the set up, integration with present structures, and worker schooling.

Another consideration is the setup time. A sophisticated box packer may additionally take weeks or even months to put in, calibrate, and take a look at earlier than it’s completely operational. This can result in quick disruptions inside the packing and achievement device. Businesses need to plan this transition cautiously, preferably in the course of slower seasons, to reduce the impact on order processing.

However, it’s important to take into account that this in advance investment is just that—an investment. Over time, the box packer pays for itself in saved difficult paintings, faster fulfillment, reduced returns, and lower material charges.

Maintenance and Technical Support

Like any advanced piece of system, the sphere packer calls for normal maintenance to feature at pinnacle efficiency. This consists of software program updates, hardware calibration, and espresso part replacements. If left out, even a minor hassle can halt operations, major to achievement delays and frustrated customers.

That’s why dependable technical assistance is vital. Businesses want to pick out a field packer dealer appeared for awesome customer service, rapid response times, and entire protection programs. Some companies even provide remote tracking and diagnostics, so issues can be detected and addressed earlier than they emerge as most critical issues.

Downtime can be highly-priced, specifically at some point of high-quantity periods. It’s vital to have contingency plans and access to backup packing techniques in case the field packer is in short out of provider.

Compatibility with Legacy Systems

Many warehouses nevertheless operate the use of older stock and order manipulate structures. Integrating a contemporary area packer into this old tech environment may be complex. Compatibility problems can reason delays, records mismatches, or maybe incorrect order packing.

To keep away from this, organizations ought to spend money on middleware or improve their legacy systems to make certain seamless communication between platforms. This technique can upload to the general price and complexity of adopting a container packer, however it’s frequently vital for long-term success.

In a few times, companies may additionally additionally choose out to put in force the field packer in ranges, starting with a particular branch or product line to check and refine the integration approach earlier than scaling up.

The Environmental Impact of Smart Packing

Sustainability Goals in Packaging

Sustainability is no longer a facet word—it’s a riding pressure in the returned of many shopping choices. Brands that prioritize green practices are gaining greater loyal clients, and the sector packer is full-size to that transformation. By ensuring every bundle uses the minimal amount of materials, the box packer enables reduce the general environmental footprint of e-trade.

For businesses aiming to satisfy enterprise sustainability dreams or observe international policies, the field packer offers measurable effect. By reducing down on wasted vicinity, decreasing carbon emissions from transportation, and minimizing the use of non-recyclable fillers, the sector packer helps each ethical operations and long-time period financial savings.

Additionally, some container packer structures can comprise eco-friendly packing substances, biodegradable adhesives, or even use sun-powered operation modules—further lowering environmental impact.

Eco-Friendly Materials and Box Packers

The modern container packer isn’t always pretty a great deal reducing the amount of packaging—it’s additionally about enhancing the quality of materials used. With developing get proper of entry to to recycled and biodegradable materials, organizations can now align their sustainability objectives with clever packing automation.

Advanced subject packer machines are like minded with a number of inexperienced materials which incorporates recycled corrugated cardboard, plant-primarily based completely plastics, and water-based adhesives. These picks no longer best lessen landfill contributions but additionally cater to environmentally aware customers.

In addition, some box packer systems come with capabilities that track and report on material utilization. This enables groups monitor their sustainability efforts, alter their techniques in real-time, and share improvement with stakeholders and customers.

The Future of the Box Packer

Predictive Packing and AI

The destiny of clever warehousing is predictive—and the sphere packer is important the charge. Soon, discipline packers received’t just react to orders in real-time; they’ll are awaiting what’s coming. Using system reading and fashion evaluation, destiny field packer systems will anticipate order patterns and put together bins earlier.

Imagine a tool that knows your Black Friday rush is coming and begins pre-sizing, reducing, and staging boxes primarily based on preceding years’ data. Or one which acknowledges a client’s recurring orders and creates a custom packing workflow for performance. That’s the electricity of predictive AI—and it’s no longer a long manner off.

This sort of foresight will dramatically reduce lead instances, limit bottlenecks, and offer greater consistency in client revel in. As AI continues to adapt, the sector packer will become even more self sufficient, making picks and changes in real-time without the want for human oversight.

Global Trends in Automation

Globally, warehouses are shifting in the direction of completely computerized fulfillment facilities, and the field packer is a cornerstone of this fashion. From North America to Europe and Asia, industries are embracing clever packaging as a manner to live aggressive, lower prices, and beautify sustainability.

Major logistics companies and e-trade giants are making an funding heavily in R&D to push the bounds of what the container packer can do. We’re seeing innovations like 3-d object scanning, drone-assisted packing logistics, and even voice-controlled systems for real-time modifications.

In the near destiny, container packer generation will probably combine with self maintaining delivery structures and drone delivery systems, developing a completely interconnected fulfillment environment from warehouse to doorstep.

Case Studies: Box Packer in Action

Amazon and Large-Scale Fulfillment Centers

when it involves logistics innovation, Amazon is usually at the forefront—and the field packer plays a key function in its hyper-inexperienced operations. Amazon makes use of a aggregate of smart box packer structures that have a look at each order, pick the most acceptable field length, and package objects in seconds.

These systems are essential for the duration of top seasons whilst Amazon fulfills tens of thousands and thousands of orders consistent with day. The field packer helps make sure timely transport while decreasing hard work fees and minimizing packaging waste. Their investment in automation has no longer best boosted efficiency but also allowed them to scale operations at an outstanding fee.

SMEs Leveraging Box Packers

It’s no longer genuinely the large gamers that advantage. Small and medium-sized corporations (SMEs) at the moment are turning to discipline packers to diploma the playing area. One on-line save selling eco-friendly cosmetics used a compact subject packer to reduce packing time with the aid of way of 70%, reduce material waste thru 40%, and remove the need for seasonal temp hires.

Another example is a local electronics hold that incorporated a clever container packer into its Shopify-based totally fulfillment setup. Orders have been packed and labeled automatically, and delivery pace progressed a lot that customer reviews stated the fast turnaround as a key motive for repeat purchases.

These case research display that with the proper approach and tool, any commercial company—regardless of length—can gain from a box packer.

Human Labor vs Automation in Packing

Redefining Workforce Roles

The advent of the field packer into present day warehouses has sparked an critical communique about hard work: what takes place to the human body of people? Rather than changing jobs, many groups are using automation to decorate them. The box packer handles repetitive, bodily taxing responsibilities—like lifting, folding, and sealing—allowing personnel to reputation on greater professional roles.

Instead of spending hours manually selecting and constructing containers, employees can now control packing structures, display screen excellent assurance, and oversee logistics float. This shift would not take away jobs—it evolves them. Employees grow to be gadget supervisors, technicians, or statistics analysts who help the sector packer run more efficaciously.

This transition additionally improves place of job safety. Back accidents and repetitive strain problems are not unusual in manual packing roles. By letting the box packer take over the heavy lifting, corporations reduce employee fatigue, absenteeism, and harm-related claims.

Training and Upskilling Opportunities

As the box packer turns into a warehouse staple, new training opportunities get up. Employees are learning to perform, troubleshoot, and even code the systems that run these machines. This upskilling no longer simplest increases task satisfaction but additionally prepares employees for the destiny of automation.

Forward-wondering organizations offer certifications in box packer machine operation, predictive renovation, and software program integration. These talents are in high demand across logistics, production, and supply chain sectors, giving employees long-term career blessings.

Businesses that offer this education are also much more likely to preserve employees. Rather than fearing automation, personnel who’re empowered with new data view the container packer as a device for increase—now not a hazard.

Box Packer ROI: What the Numbers Say

Performance Metrics and KPIs

Let’s talk numbers. Businesses that undertake a field packer normally music severe key overall overall performance indicators (KPIs) to degree ROI. These consist of order packing velocity, packaging material monetary savings, hard work cost cut price, and accuracy rate. A nicely-optimized field packer can device up to 800 programs regular with hour with an errors fee beneath 0.1%.

Material financial savings by myself can be large. By minimizing void fill and the usage of right-sized packing containers, agencies file as much as 35% savings on cardboard and filler materials. Labor economic financial savings range between 30% to 50%, counting on how many guide roles are replaced or restructured.

Accuracy upgrades additionally effect the lowest line. With fewer packing mistakes and damages, go returned charges drop with the useful resource of as plenty as 25%. That manner a lot much less coins spent on refunds, replacements, and contrary logistics.

Long-Term Financial Benefits

The preliminary rate of a discipline packer may seem steep, but most corporations see complete ROI inside 12–24 months. This is in particular authentic for high-volume e-commerce operations in which even minor profits are accelerated across heaps of orders.

Moreover, a field packer permits corporations to scale without the need to growth warehouse space or hire greater seasonal staff. This makes increase extra feasible and charge-powerful.

By automating packing, organizations moreover benefit more perception into operations. Data gathered from the box packer may be analyzed to forecast call for, enhance stock manipulate, and streamline transport schedules. These efficiencies electricity lengthy-term profitability and prepare organizations for destiny growth.

Final Thoughts: Embracing the Box Packer Revolution

The modern-day success center is converting—and the sphere packer is at the middle of that transformation. It’s not most effective a system; it’s a picture of what’s feasible while innovation meets logistics. By automating one of the most time-ingesting and blunders-willing steps in the deliver chain, the box packer gives you real, measurable effects for companies of all sizes.

Whether you run a global e-exchange empire or a developing on-line boutique, integrating a clever field packer can reduce fees, improve performance, and raise your brand. It complements sustainability, improves customer pride, and lets in your organization to popularity on better-charge duties.

We’re coming into an technology wherein packaging isn’t only a beneficial necessity—it’s a strategic advantage. The box packer is greater than a trend; it’s the new ultra-modern in warehousing and fulfillment.

FAQs

- What is the common fee of a box packer gadget?

The price of a discipline packer machine varies primarily based on capabilities and scale. Entry-degree models may also additionally begin round $25,000, whilst advanced systems with AI, robotics, and complete automation can exceed $250,000. - Can small agencies manipulate to pay for area packers?

Yes. Many vendors provide modular or hire-to-non-public area packer answers tailor-made to smaller operations, permitting businesses to start small and scale up. - How an entire lot time does a container packer store?

A field packer can growth packing tempo through manner of 2–3 instances compared to guide strategies, coping with as tons as 800 applications in keeping with hour with minimum errors costs.

4. Are subject packers secure for workers?

Absolutely. Modern box packer systems are designed with safety sensors, automatic shutoff functions, and ergonomic setups that lessen stress and enhance workplace safety.

5. What’s subsequent in packing automation?

Future upgrades embody predictive AI packing, drone-assisted logistics, and integration with self sustaining shipping structures. The subject packer will play a number one role in these improvements.